What Is the Paper Feed Mechanism?

Table of Contents

Understanding the paper feed mechanism is essential for anyone involved in printing and paper handling processes. This mechanism plays a crucial role in ensuring smooth operations across various devices.

For more insights, check out our detailed guide on the friction feeder and our article “Paper Feeding Technology: Understanding the Friction Feed Method”

The Paper Feed Mechanism

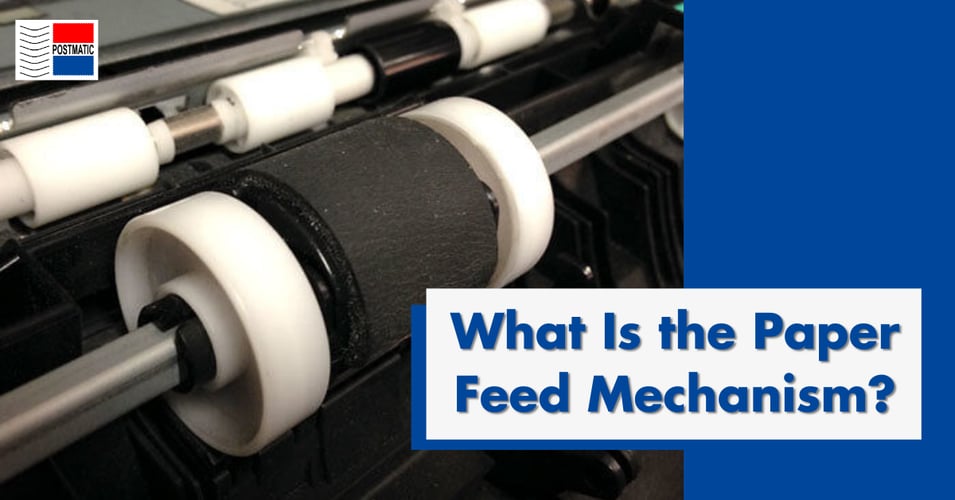

The paper feed mechanism transports paper through printers, copiers, or other machines. It reduces the likelihood of jams and ensures the device operates smoothly. By managing paper movement, this mechanism supports various printing processes, enhancing both speed and productivity.

What Is Paper Feeding Technology?

Modern paper feeding technology uses innovative methods to optimize paper handling across various applications. It employs a system of sensors, rollers, and automated mechanisms to ensure consistent and precise paper movement during printing or processing.

Sensors allow for real-time monitoring of paper conditions, detecting issues like jams or misalignment. Rollers are able to handle various paper weights, textures, sizes, and types, which allows users to switch between different media without manual intervention. This versatility not only improves productivity but also expands the range of printing options available, making it easier to produce everything from standard documents to specialized prints.

Additionally, advancements in software control systems have enabled better synchronization of paper feeding with other machine functions, streamlined workflows, and reduced downtime. As a result, businesses achieve higher productivity while maintaining quality output.

What Is the Function of the Paper Feeder?

The primary function of the paper feeder is to supply paper into the device with precision. This crucial component ensures each sheet is correctly aligned and fed at the right moment, which is essential for maintaining printing quality and preventing jams. By ensuring a consistent and reliable paper supply, the paper feeder plays a vital role in optimizing the performance and longevity of the printing device.

What Are the Methods of Feeding Paper?

There are several paper feeding methods, each of which caters to specific needs and enhances the efficiency of printing and other paper-related processes:

- Friction Feed: This method utilizes friction rollers to move paper, ensuring precise alignment and consistent feed rates. It's common in applications where speed is essential and the paper size is uniform. Friction feed systems are versatile and can handle various types of paper, including light stock and heavy cardstock.

- Suction Feed: Suction feed systems employ a vacuum mechanism to lift and guide paper into the machine. This method is particularly effective for handling thin or delicate papers, which may be prone to jamming or misalignment. The suction mechanism provides gentle yet effective handling, making it suitable for a broad range of printing tasks.

- Continuous Feed: Ideal for high-volume tasks, this method involves a steady flow of paper, allowing for uninterrupted operations. Continuous feed systems are designed to handle large quantities of paper, making them perfect for commercial printing or mass production environments. They often come with automated features that minimize downtime and enhance productivity.

What Is the Feed Mechanism?

The purpose of the feed mechanism is to provide stable and consistent paper supply in various devices, such as printers, copiers, and other paper-handling equipment. This mechanism plays a crucial role in feeding the paper accurately and continuously, preventing jams and ensuring smooth operation.

A well-functioning feed mechanism not only enhances the efficiency of the devices, it also contributes to the overall quality of the printed output, ultimately leading to higher customer satisfaction and reduced operational costs. Of course, regular maintenance of the feed mechanism will further improve reliability and performance.

Conclusion

The paper feed mechanism is integral to the functionality of printing and paper-handling devices, playing an important role in ensuring paper flow. To further improve your paper handling efficiency, consider exploring advanced feeders or upgrading existing systems. For more detailed information, contact us to explore our range of solutions.